Nukote Coating Systems polyurea products were specified by the client in Japan, prior to the initiation of the project in Algeria. Nukote maintains a strong relationship with the client that covers several projects globally.

Daewoo Construction and Engineering (DCE) engaged Nukote to supply the products specified and the required plural component equipment directly to the project site. Daewoo also engaged Nukote technical teams to prepare the application method statements, the quality assurance, inspection and testing programs and the application teams and supervisory personnel for the installation on site.

This project is a prime example of the total package Nukote can provide; product, specification, application and equipment systems.

This project is currently the largest area fertilizer production facility in the world. Due to the projects sensitive location in North Africa, the client and the contractor requested that Nukote carry out the project management and application works for the project.

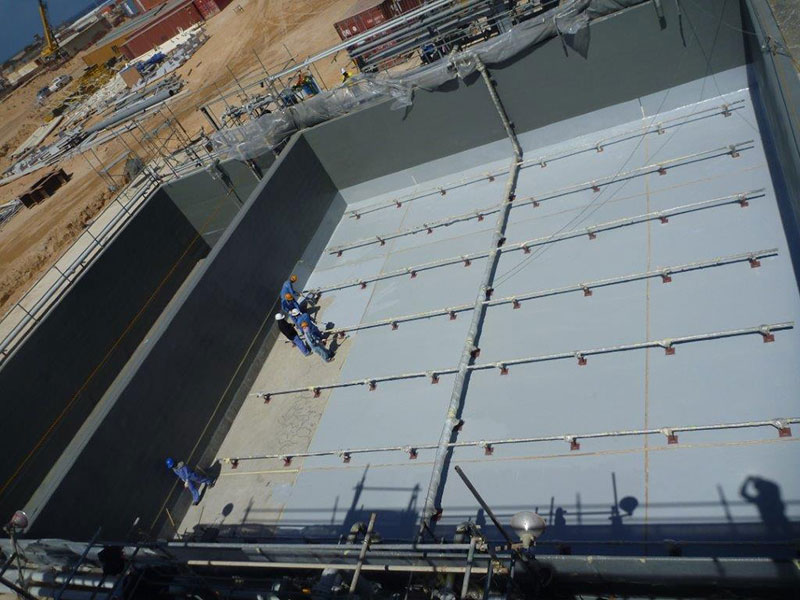

Nukote XT was applied in various locations within the project which included; Primary Containment of Process Basins, Secondary Containment of Chemical Storage Bunds and Waste Water Process Tanks.

The largest application area was the chemical treatment and neutralization demi pits, which were completed in ten working days. The concrete substrate required skim coating of voids using Nukote epoxy filler composite system to rid the substrate of defects.

All three pits were fitted with a series of brackets to support process pipe structures. This was recognized as a critical area for the application works. A site specific detail (pipe termination wrap) was designed and utilized to ensure that the coating was properly terminated at pipe brackets and other penetrations.

Two secondary containment bund areas were also coated, to ensure that Sulphuric Acid and Caustic Soda were properly contained should spills of leaks occur. This consisted of one bund area for caustic soda tanks and one bund area for sulphuric acid tanks.

Three additional bunded areas required protection with Nukote XT+. Two mechanical pump areas, one for each caustic and sulphuric acid liquid distribution, and one chemical dosing area where a variety of process chemicals are injected for treatment and neutralization in the plant aeration pits.

Ring beam protection, which is a common corrosion problem that occurs where a steel tank sits on a concrete base, was addressed with formal termination.

Chemical attack and differential thermal expansion rates can cause failure of jointing systems allowing corrosive vapor or liquid to ingress under the tank. Corrosion can then progress rapidly, leading to perforation and leakage with associated environmental damage, tank repairs costs and lost production.

Nukote was involved from the specification phase to implementation and completion phases, which included the following; full specification and detail design, product and application equipment supply, project management, quality assurance and inspection program development and management, and specialist coating application teams.

Material and equipment shipments were completed will in advance of the application works. Nukote project managers and application teams were flown in from the Middle East and Singapore to apply and manage the works.

Nukote completed the project within the desired timeline and exceeded all expectations of our client. On completion of the project the client and contractor engared Nukote again for another scope of work that entailed 2800 m2 of primary containment coating for effluent pits.

Client: Mitsubishi Heavy Industries

Distributor: Nukote Coating Systems

Contractor: Daewoo Engineering & Construction

Applicator: Nukote Coating Systems

System: Nukote XT Plus

Area: 6,500 M²